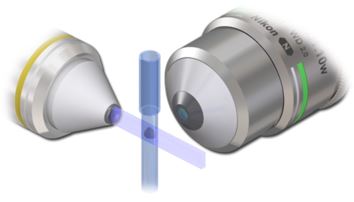

In the past, we have published several different blogs and whitepapers relating to both Raman and fluorescent confocal microscopy. Therefore, there is no need for us to repeat the basics here, so we will simply point out that while traditional confocal microscopes provide excellent spatial resolution, they do so at the trade-off of producing extremely large intensities at the sample. For example, if a 5mW laser is focused down to a 1-micron spot at the sample, it will result in an optical intensity 100 times larger than the surface of the sun. As a result, confocal microscopes are often limited because of the photothermal and photochemical damage that they induce on biological samples. One mitigation technique which we discussed in previous posts is to utilize two-photon microscopy to lessen the photochemical damage, but this does little to reduce the photothermal impact. Nowadays, the number one technique for mitigating photothermal damage is to use a method known as light-sheet microscopy, whereby the excitation and collection axis are decoupled by utilizing two different microscope objectives as shown in the figure below.

Light-sheet microscopy allows for the excitation objective to produce a laser beam that is astigmaticly focused, resulting in a planer sheet of light at the sample instead of a focused spot. When combined with a high numerical aperture collection objective, light-sheet microscopy provides the z-resolution and signal-to-noise ratio benefits of the confocal geometry without the throughput disadvantages of conjugate pinholes. Exact details about how the light sheet is generated whether it be through cylindrical lens, scanning, or Bessel beams is beyond the scope of this blog. Instead we will focus on how the use of a dual-beam approach can mitigate artifacts introduced from the illumination.

One of the most common problems with light-sheet microscopy is the fact that optically opaque spots within the sample can cause an artifact, which appears in the image as dark stripes. While early light-sheet microscopy dealt with this issue by moving the sample, most modern systems use a dual-beam approach instead. This dual-beam method uses two different objectives (or in some cases, four) to illuminate the sample from either side, significantly reducing the probability of inducing stripe artifacts. While, in theory, this can be achieved using a single input fiber optic, which is split with a partially reflective mirror and sent through two different beam paths, it is far simpler to use a laser combiner with two different outputs. Ideally, each output is balanced to provide the same power output. Additionally, it should be noted that depending on the system configuration (which again is beyond the scope of this blog post) you may or may not want to operate both beams simultaneously. As a result, it is important that the laser source has the ability to quickly switch back and forth between the two fiber-coupled outputs.

As we have previously discussed, the LaserBoxx L6Cc & L4Cc Combiners from Oxxius have been explicitly designed for fluorescence microscopy, featuring up to six different laser sources colinearly combined, and individually addressable. But what we have not previously discussed is the fact that the LaserBoxx has an optional extension module, which is specifically designed for dual-beam light-sheet microscopy. The MDL-MDUAL add-on provides two outputs, which can be balanced to provide an output, with a split ratio of +/- 5% accuracy. Additionally, the MDL-FSTM fast switching option can be added on for light sheet applications where the user wishes to switch back and forth between the two beams. The MDL-FSTM offers swathing speeds of up to 30Hz with less than 5ms switching time.

If you would like to get a more detailed understanding of the LaserBoxx, you can check out our white paper titled “Multi-Wavelength Laser Sources for Multi-Color Fluorescence Microscopy,” or click here to visit the product page for more detailed technical specifications. As always, you can also talk to one of our laser experts today by calling 1-636-272-7227.

SHIPS TODAY

SHIPS TODAY