In the last installment of our Laser Diode Fundamentals series, we took a deep dive into the underlying physical properties behind the longitudinal mode structure of laser diodes. In that blog post, we explained the advantages and disadvantages to both multi-longitudinal mode and single longitudinal mode diode lasers. In this blog post, we are going to expand on what we learned about single longitudinal mode diodes lasers and take a look at a wide range of stabilization techniques which are used to ensure that a laser maintains single mode performance during its operation.

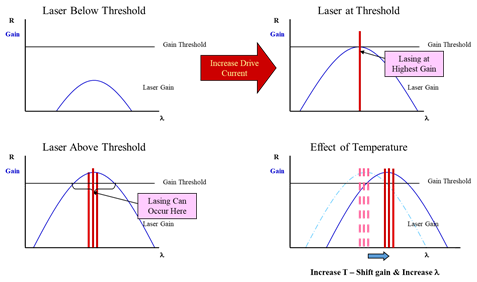

To briefly review the previous post, we established that the interplay between the gain threshold, gain bandwidth, and longitudinal mode spacing is what ultimately determines whether or not a diode operates as a single- or multi-mode device. We further went on to explain that for only one longitudinal mode to exist the gain threshold needs to be significantly high and the gain bandwidth substantially narrow to allow for only one mode to lase at a time. What we did not explain in that post is that the diodes gain curve is dependent on both the junction temperature and drive current. While a detailed analysis of why the current and temperature affects the gain curve is beyond the scope of this post, the diagram below does an excellent job of illustrating the basic principles. This figure shows that as the current in increases or decreases the height of the gain curve will increase or decreases and that as the temperature increases or decreases the curve with red shift or blue shift.

With this knowledge, it should now be evident that for a standard free running laser diode, the only way that single longitudinal mode operation can be achieved is by precisely controlling both the drive current and temperature. While this is possible, it is not only technically challenging to make, but it is also reasonably impractical because it limits the functionality of the diode. For example, it limits the environmental conditions for laser operation and prevents the user from adjusting the output power of the laser diode. Luckily there are a wide variety of techniques which have been developed for selectively modifying the gain threshold by either increasing or decreasing the cavity loss at specific wavelengths. As a result, as the current and temperature of the diode are varied and single mode operation is always maintained.

It would take far too long to dive into the physics behind each of the methods used so in this blog post we are going to simply list some of the standard techniques and provide a brief overview.

- Mode Selection by Etaloning – Unlike the other methods we will discuss below when using etaloning instead of modifying the gain threshold we are altering the allowed modes in the laser itself. By inserting two parallel glass plates into the laser cavity, the reflections from each surface create a secondary hole known as an etalon. The resultant “cavity in a cavity” can now only sustain longitudinal modes which both resonators allow. If adequately designed so that the permitted modes of each cavity only overlap at one point this will result in a single longitudinal mode operation. While this method is extremely useful, it is difficult to construct and align, so it is not often used with laser diodes.

- Mode Selection by Injection Seeding – Injection seeding is a method where the desired laser frequency is coupled into the laser cavity by an external source. This can either be a separate low power single longitudinal mode laser or a grating which only reflects the specific wavelength of interest back into the cavity. This causes the laser “lock-on” to the frequency of the seed giving that mode preferential gain.

- Mode Selection by Using a Grating as Output Coupler – By replacing the output coupler with a grating, you combine the two gain threshold values into one function. This results in a decoupling of the gain threshold from the temperature and current dependences of the gain material. This category of a laser diode is generally referred to as an external cavity laser since unlike most other diode laser designs it no longer uses the front facet as the part of the resonator making it easier to insert other optical elements into the cavity. These days the most common configuration of an external cavity laser (ECL) is to use a volume Bragg grating for an output coupler since the thermal expansion coefficient of glass is rather small, decoupling its performance from the laser temperature.

- Mode Selection by Diode Etching – Instead of utilizing an external grating, the grating can also be etched into the diode itself to create an alignment-free monolithic diode laser with similar properties as external cavity laser sources. The two most common configurations of his design are distributed feedback (DFB) and distributed Bragg reflector (DBR) lasers. In the case of DFB laser diodes, the grating is etched across the entire gain region of the diode, whereas in a DBR laser the grating is etched into a dedicated feedback region where there is no active gain. This makes them smaller and easier to manufacture than ECLs, but they are limited in the power they can generate and are highly susceptible to variations in temperature and current. The susceptibility to temperature and current is not necessarily a bad thing though, for example, DFB and DBR lasers can both be frequency tuned using current or temperature control which is useful in a wide range of telecommunications and spectroscopy applications.

Here at RPMC Lasers, we have over 20 years of experience with diode lasers and are readily available to assist you in not only deciding which of our standard off the self-laser diodes are ideal for your application, but we are also able to offer countless custom laser diode packaging configurations with a wide range of integrated optics include all of the designs discussed above. For more information about our wide variety of laser diodes, you can click here, and for more information about laser diode fundamentals be sure to visit our Lasers 101 page.

SHIPS TODAY

SHIPS TODAY