Continuing with our recent theme of application for laser diode bars and stacks, in this post we will take a look at laser cladding. If you haven’t already read our previous post titled “Understanding Laser Diode Arrays,” or have a basic understanding of laser diode bars and stacks we’d highly recommend you check out that post before reading this one.

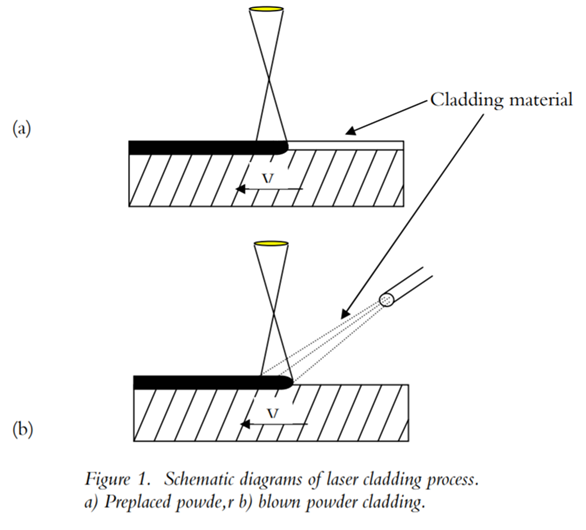

By definition laser cladding, also known as laser deposition, is a material processing technique in which a small amount of material is added to the surface of another material in a controlled manner. This is typically done in one of two ways, either by blowing a focused jet of powdered material in a buffer gas coincident with the laser spot or by depositing the material on the surface first and then scanning over it with the laser. In both processes, shown below, the material cladding material and the surface of the base material are heated by the laser causing the two to fuse together. This process results in the surface of the material taking on the properties of the cladded alloy instead of the material itself. As a result, cladding allows for the use of lower cost materials to be used in the machining process greatly reducing the over all cost of the part in question.

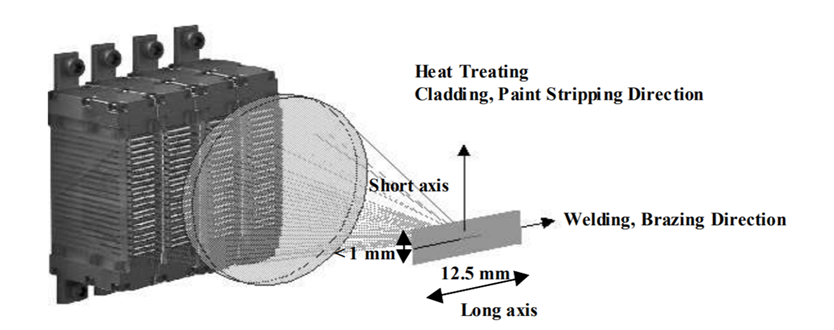

High power laser diode stacks are ideal for this application because of their uniquely astigmatic beam profiles, which makes it very easy to focus them into a line as shown in the figure below. Additionally the over lapping mode structures of the individual ridges in each bar with the stack produces a fairly uniform flat-top beam profile along the long axis of the focused beam. This provides a much need uniformity cladding process which is much more difficult to achieve with more traditional high power laser sources such as Nd:YAG and CO2 lasers.

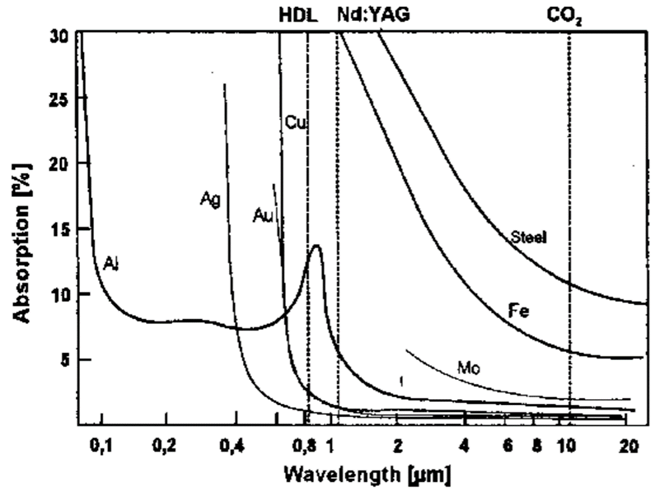

Here at RPMC, we offer laser diode stacks from Focuslight Technologies with output powers up to 7.8kW and wavelengths from 780 nm to 976 nm. This figure below show that this wavelength range, is in the sweet spot where they can be absorbed by most of the common metals used in machining particularly steel and aluminum.

For detailed technical specifications on our high power diode stacks from Focuslight Technologies click here or talk to one of our laser experts today by calling 1-636-272-7227.

SHIPS TODAY

SHIPS TODAY